Today’s fiber laser cutting machine has become an important tool indispensable in industrial production, high efficiency and high precision cutting advantages, has been trusted by many processing and manufacturing enterprises. However, although the productivity of fiber laser cutting machine is very high, but if you do not understand how to adjust the fiber laser cutting machine, we processed the product is still not up to the expected cutting effect. The following will follow us GOLD MARK to understand how to debug fiber laser cutting machine to achieve the best cutting effect it.

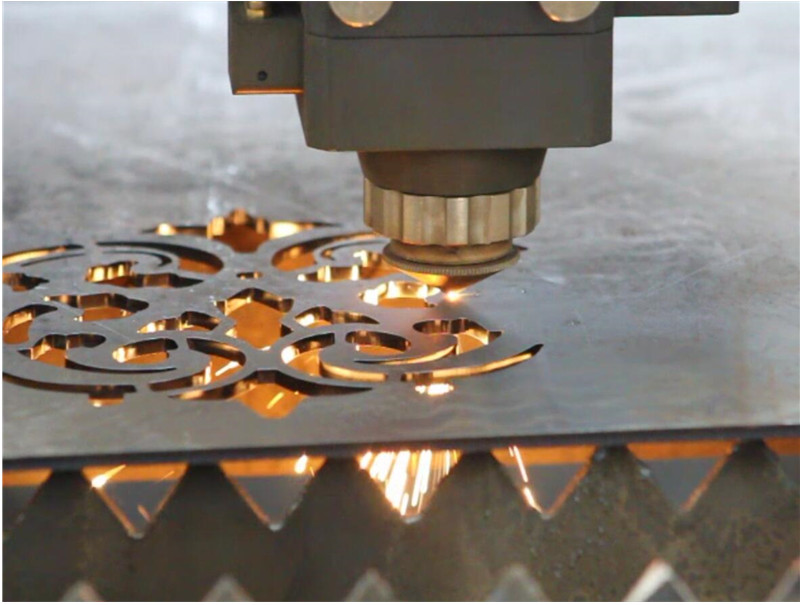

1, in the first half of the fiber laser cutting machine for debugging, we can use some debugging paper, workpiece scrap to point shooting to determine the accuracy of the focal position, moving up and down the laser head height position, the laser spot size point shooting will have a different size change. Multiple adjustments of different positions to find out the location of a small spot to determine the focal length and the position of the laser head.

2, when the laser focus of the spot is adjusted to a small point, point shooting to establish the beginning of the effect, the size of the spot effect to determine the focal position, we just need to recognize the laser spot to a small point, then this position is a better processing focal point, and then start laser cutting work.

3, fiber laser cutting machine after installation, the machine and equipment will be installed on the nozzle of a scribing device, through the scribing device to scratch a simulated cutting graphics, simulated graphics for 1m square. Built-in a circle with a diameter of 1m, the four corners are scribed on the diagonal, after scribing, using a measuring tool to measure whether the circle is tangent to the four sides of the square. Whether the length of the diagonal of the square is √2 (the data derived from the open root is about 1.41m), the central axis of the circle should equally divide the sides of the square, and the distance between the point where the central axis intersects the two sides of the square and the intersection of the two sides of the square should be 0.5m. Test the distance between the diagonal and the intersection point to determine the cutting accuracy of the device.

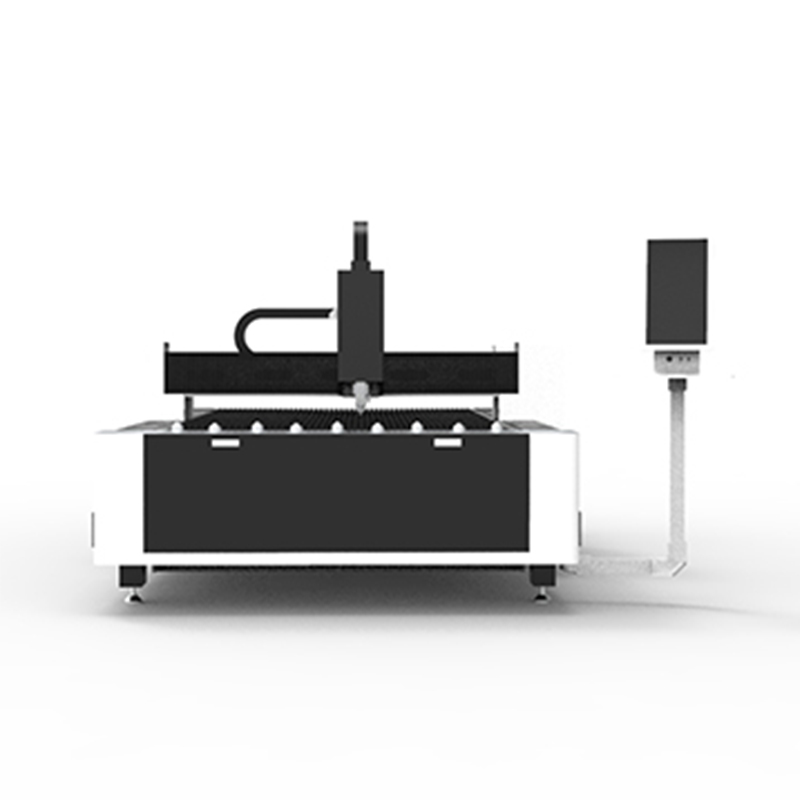

Jinan Gold Mark CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Post time: Jun-15-2021