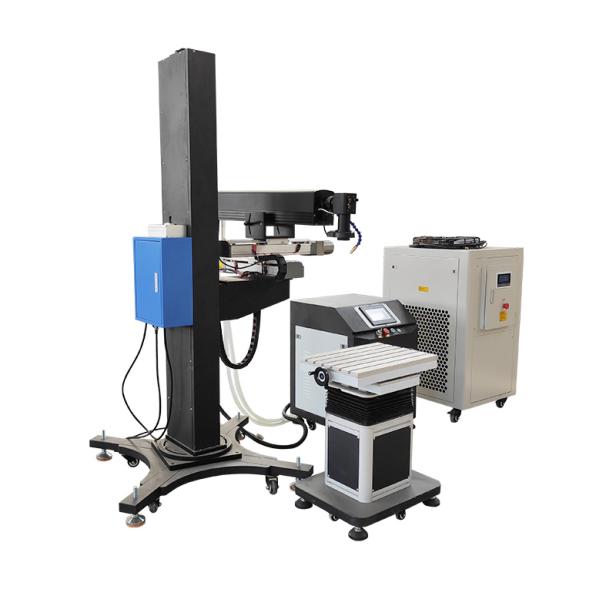

Laser welding machine is used in the field of welding, and it is one of the important aspects of the application of laser material processing technology. According to its working mode, it can be divided into laser mold welding machine, automatic laser welding machine, and laser spot welding machine , fiber laser welding machine, etc. What are the advantages of laser welding machine?

- Ø Advantages

1. After focusing laser, the power density is high. After the high-power low-order mode laser is focused, the focal spot diameter is very small.

2. The laser welding speed is fast, the depth is large, and the deformation is small. Due to the high power density, small holes are formed in the metal material during the laser welding process, and the laser energy is transmitted to the deep part of the workpiece through the small holes, and there is less lateral diffusion. The speed is fast, and the welding area per unit time is large.

3. The welding depth-to-width ratio is large, the specific energy is small, the heat-affected zone is small, and the welding deformation is small. It is especially suitable for the welding of precision and heat-sensitive parts, which can avoid post-weld orthopedic and secondary processing.

4. It can be welded at room temperature or under special conditions, and the welding equipment is simple.

5. It can weld refractory materials, such as titanium, quartz, etc., and can weld materials of different materials, such as copper and tantalum, two metals with completely different properties are welded together, and the effect is good.

6. Micro-welding can be carried out. After the laser beam is focused, a small spot can be obtained, and it can be precisely positioned, which can be applied to the assembly welding of micro and small components in mass automatic production. Not only the production efficiency is greatly improved, but also the heat-affected zone is small and the solder joint is free of pollution, which greatly improves the quality of welding

7. It can weld hard-to-reach parts and implement non-contact long-distance welding, which has great flexibility.

8. Generally, no filler metal is added. If fully protected with inert gas, the weld is free from atmospheric contamination

9. The welding system is highly flexible and easy to automate.

10. Laser welding machine Laser welding is similar to electron beam welding in many aspects, and its welding quality is slightly inferior to electron beam welding, but electron beam can only be transmitted in vacuum, so welding can only be carried out in vacuum, and laser welding technology can Applied in a wider range of work environments.

Jinan Gold Mark CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Post time: Aug-02-2022