Zininzi iindlela zokuwelda isinyithi, njenge-argon arc yendabukoukuwelda, ukuwelda kombane kunye nabanye oomatshini abaqhelekileyo bokuwelda.

Kwiminyaka yakutshanje, ukusika kwe-laser kunyewelding laserbaye bangena kwintsimi yesinyithi kunye nokwenza.Umatshini we-laser welding welding unenzuzo ebonakalayo ekusebenzeni kakuhle kunye nokulula, kwaye uye wavelisa ngokukhawuleza "i-metal welding iteration effect", enokuthi ithathe indawo ye-argon arc welding, i-welding yombane kunye nezinye iinkqubo.Ingasetyenziselwa umnyango kunye nefestile ye-hardware, imisebenzi yezandla, ukukhanya, intengiso yesinyithi, ikhitshi ye-hardware kunye negumbi lokuhlambela, i-tableware, izixhobo zasekhitshini, oomatshini bezolimo kunye namahlathi, izixhobo zonyango, izixhobo zokufaneleka kwezemidlalo kunye nezinye i-industries.Metal laser cutting, ukugoba kunye ne-welding ehlanganisiweyo isicwangciso sokusebenza.

Ziziphi iingenelo koomatshini bokuwelda belaser ngesandla?

Umatshini we-laser welding owenziwe ngesandla uphucula iziphene ze-welding ezifana ne-undercut, ukungena okungaphelelanga, i-porosity exineneyo kunye nokuqhekeka kwinkqubo ye-welding yendabuko.I-weld seam emva kwe-welding igudile kwaye intle, enciphisa inkqubo yokupolisha elandelayo kwaye igcina ixesha kunye neendleko.Kwaye zimbalwa izinto ezisetyenziswayo, ubomi obude, kwaye bunokuba novakalelo kwaye bufanelekele iindawo ezahlukeneyo.

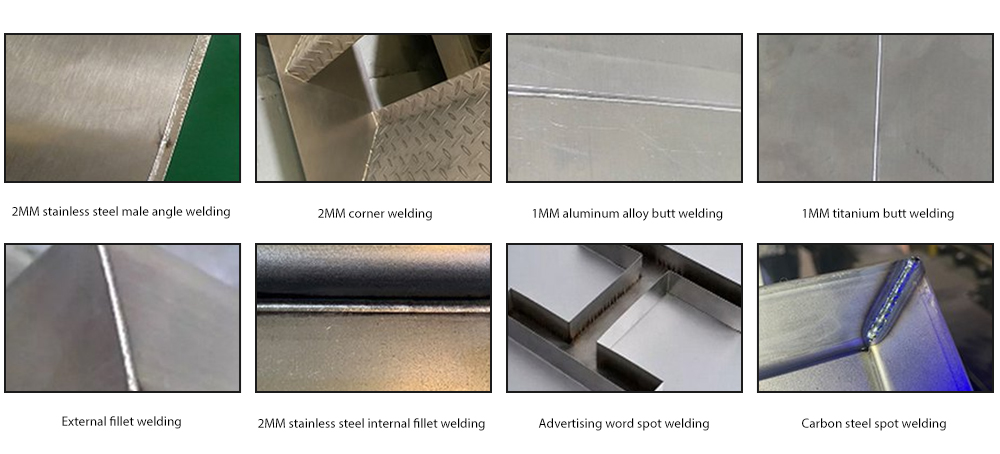

1. Seta ngokulula iiparamitha kwaye unokuqalisa kwangoko.Emva kokutshintsha i-nozzle, akunandaba nokuba i-welding flat, i-angle yangaphakathi, i-angle yangaphandle, i-welding overlap, njl.

2. I-laser beam yi-avareji, umgangatho ophezulu, uqhubekayo kwaye uzinzile, kwaye umboniso uphakathi.Isiphumo se-welding siyafana kungakhathaliseki ukuba sisiqalo okanye siqhelekile, kwaye akuyi kubakho iingxaki ezifana ne-pores, i-weld bead, ukungena kwe-weld, kunye ne-workpiece deformation.

3. Kwizinto zetsimbi ezifana nentsimbi engatyiwayo, i-galvanized sheet, ipleyiti ebandayo, njl. njl., inokugqiba i-welding ye-welding ekhawulezayo, ephindwe kaninzi kunezinye iindlela ze-welding.

Ukuqaliswa kwe-Handheld Laser Welding Machine

I-laser welder ephathwayo sisixhobo esitsha esithatha indawo ye-welding yemveli.Inesantya sokuwelda ngokukhawuleza kunewelding yemveli.

1. Ilula, ifundeka lula, inovelwano kwaye iluncedo.Ukwamkela isakhiwo esidibeneyo, umqhubi akafuni kakhulu, uqeqesho olulula lunokusetyenziswa, ukusebenza okulula, ngokukhawuleza ukuqalisa;i-welding multi-dimensional, enovelwano kwaye ifanelekile;

2. Ixabiso eliphantsi lotyalo-mali kunye neendleko zokulondoloza.I-laser ebanjwe ngesandla, akukho mfuneko yetafile ye-welding echanekileyo, i-consumables encinci, ukuthunyelwa kwezixhobo eziphantsi kunye neendleko zokuzigcina, kunye nokusebenza kweendleko eziphezulu;

3. Gcina umsebenzi.I-laser ye-laser ebanjwe ngesandla ikhawuleza, ikhawuleza kune-welding yendabuko, kwaye i-weld seam emva kwe-welding ihamba kakuhle kwaye intle, inciphisa inkqubo yokugaya yokulandelela, ukonga ixesha kunye neendleko;

4. Umgangatho olungileyo.I-laser welding workpiece ayinayo i-deformation, akukho scar ye-welding, kwaye i-welding yomelele;

5. Ukhuseleko lokhuseleko.Inomsebenzi wokukhusela ukhuseleko loqhagamshelwano ukukhusela ukukhanya ukuba kukhutshwe ngephutha, kunye nokuqinisekisa ukuba ukukhanya kufakwe emva kokudibanisa nentsimbi.Ixhotyiswe ngeeglasi ezikhuselayo ze-laser, ezifuna ukunxitywa xa zidibanisa.Ukuqinisekisa ukhuseleko.

Umatshini we-handheld mirror welding uneentlobo ezininzi ze-6 zeendawo ezikhanyayo, ezinokugqiba i-fillet welding, i-vertical welding, i-welding ye-talor, kunye ne-stitch welding, kwaye iphendule kwiintlobo ezahlukeneyo zezicelo zesicelo.

Iindawo zesicelo eziphambili

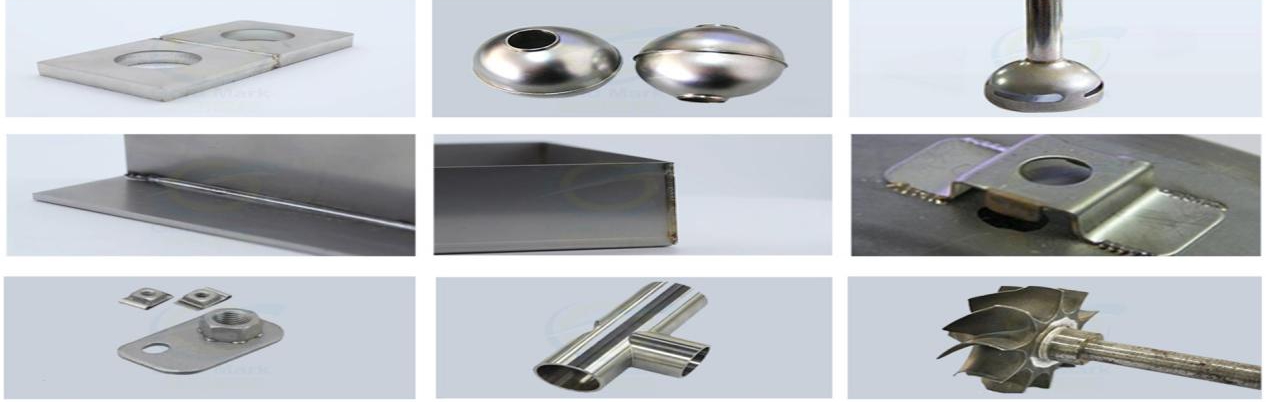

Ukusetyenzwa kwesinyithi emakhitshini nasezindlini zokuhlambela, izinyusi, iishelufu, iihardware, izixhobo zokwakha, iingcango kunye neefestile, izigqubuthelo zomngxuma, izithinteli zokungcola, imisebenzi yezandla kunye namanye amashishini, kunye nelaser welding of sheet and pipe materials kumashishini afana noomatshini bobunjineli kunye nokuhanjiswa kweenqanawa.

Idatha enokuweldable

Carbon steel, stainless steel, aluminiyam ialloy, ubhedu, ikopolo, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy kunye nezinye izinto zentsimbi.

IJinan Gold Mark CNC Machinery Co., Ltd.lishishini lobugcisa obuphezulu obukhethekileyo kuphando, ukuvelisa kunye nokuthengisa oomatshini ngolu hlobo lulandelayo: I-Laser Engraver, iFiber Laser Marking Machine, i-CNC Router.Iimveliso zisetyenziswe ngokubanzi kwibhodi yentengiso, ubugcisa kunye nokubumba, i-architecture, i-seal, ilebula, ukudweba imithi kunye nokukrola, umhlobiso wamatye, ukusika kwesikhumba, amashishini eengubo, njalo njalo.Kwisiseko sokufunxa itekhnoloji ephezulu yamazwe ngamazwe, sibonelela abathengi ngeyona mveliso iphambili kunye nenkonzo egqibeleleyo emva kokuthengiswa.Kwiminyaka yakutshanje, iimveliso zethu azithengiswanga kuphela e-China, kodwa nakwi-Asia-mpuma ye-Asia, kuMbindi mpuma, eYurophu, eMzantsi Melika nakwezinye iiMarike zaphesheya.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Ixesha lokuposa: Feb-21-2022