There are many methods for metal welding, such as traditional argon arc welding, electric welding and other ordinary welding machines.

In recent years, laser cutting and laser welding have entered the field of metal processing and forming. The hand-held laser welding machine has obvious advantages in efficiency and convenience, and has rapidly produced the “metal welding iteration effect”, which can almost replace argon arc welding, electric welding and other processes. It can be used in door and window hardware, handicrafts, lighting, metal advertising, hardware kitchen and bathroom, tableware, kitchen appliances, agricultural and forestry machinery, medical equipment, sports fitness equipment and other industries.Metal laser cutting, bending and welding integrated processing plan.

What are the advantages of handheld laser welding machines?

The hand-held laser welding machine improves welding defects such as undercut, incomplete penetration, dense porosity and cracks in the traditional welding process. The weld seam after welding is smooth and beautiful, which reduces the subsequent polishing process and saves time and cost. And there are few consumables, long life, and it can be sensitive and suitable for various environments.

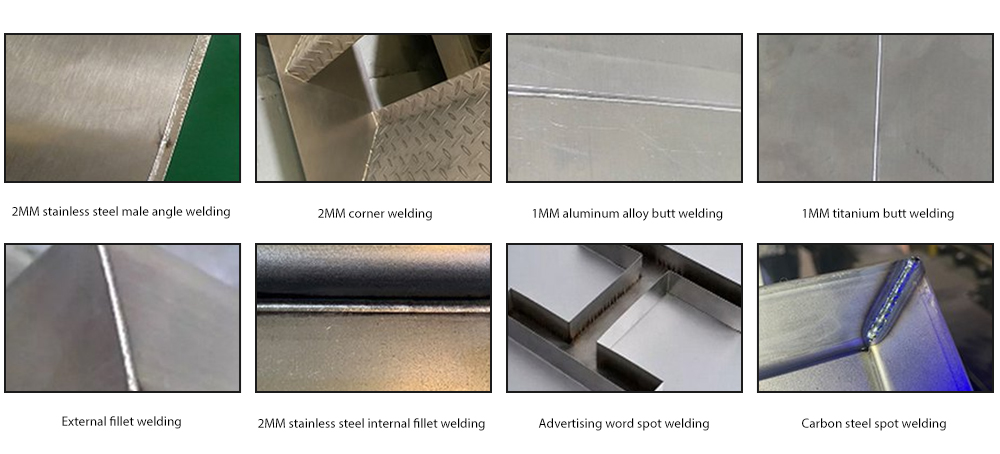

1. Simply set the parameters and you can get started immediately. After changing the nozzle, it doesn’t matter whether it is flat welding, internal angle, external angle, overlap welding, etc.

2. The laser beam is average, high quality, continuous and stable, and the reflection is average. The welding effect is the same regardless of whether it is a beginner or a familiar one, and there will be no problems such as pores, weld bead, weld penetration, and workpiece deformation.

3. For metal materials such as stainless steel, galvanized sheet, cold plate, etc., it can basically complete one-time rapid welding, which is several times faster than other welding methods.

Introduction of Handheld Laser Welding Machine

The handheld laser welder is an innovative device that replaces traditional welding. It has a faster welding speed than traditional welding.

1. Simple, easy to learn, sensitive and convenient. Adopting an integrated structure, the operator is not very demanding, simple training can be used, simple operation, quick to get started; multi-dimensional welding, sensitive and convenient;

2. Low investment cost and maintenance cost. Hand-held laser welding, no need for precision welding table, less consumables, low equipment deployment and maintenance costs, and high cost performance;

3. Save labor. Hand-held laser welding is faster, faster than traditional welding, and the weld seam after welding is smooth and beautiful, reducing the follow-up grinding process, saving time and cost;

4. Good quality. The laser welding workpiece has no deformation, no welding scar, and the welding is strong;

5. Safety protection. It has a contact safety protection function to prevent the light from being emitted by mistake, and to ensure that the light is welded after contact with the metal. Equipped with laser protective glasses, which need to be worn when welding. To ensure safety.

The handheld mirror welding machine has as many as 6 types of light spots, which can complete fillet welding, vertical welding, tailor welding, and stitch welding, and respond to various types of application requests.

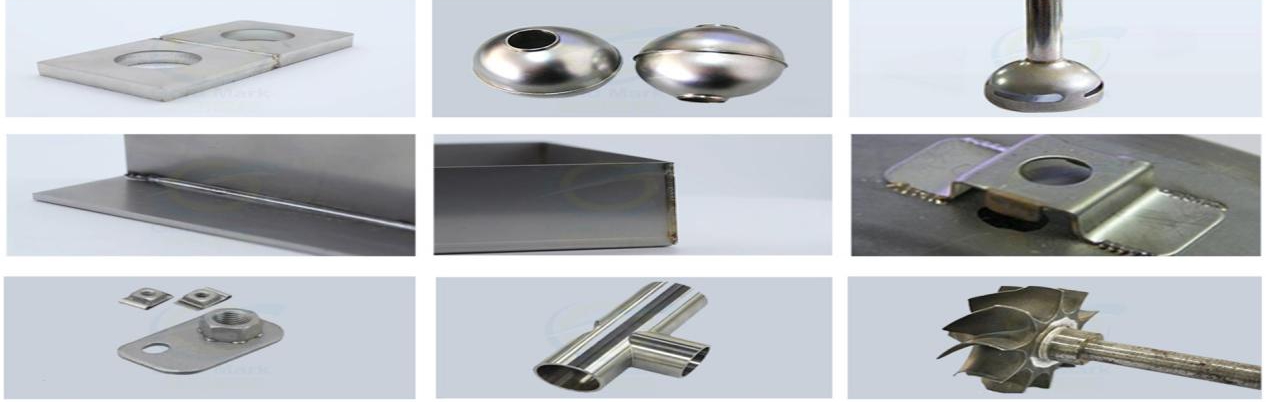

Main application areas

Sheet metal processing in kitchens and bathrooms, elevators, shelves, hardware, building materials, doors and windows, manhole covers, dirt interceptors, handicrafts and other industries, and laser welding of sheet and pipe materials in industries such as engineering machinery and ship mooring.

Weldable data

Carbon steel, stainless steel, aluminum alloy, brass, copper, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy and other metal materials.

Jinan Gold Mark CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Post time: Feb-21-2022