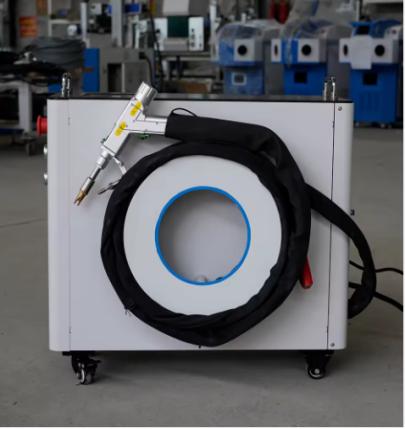

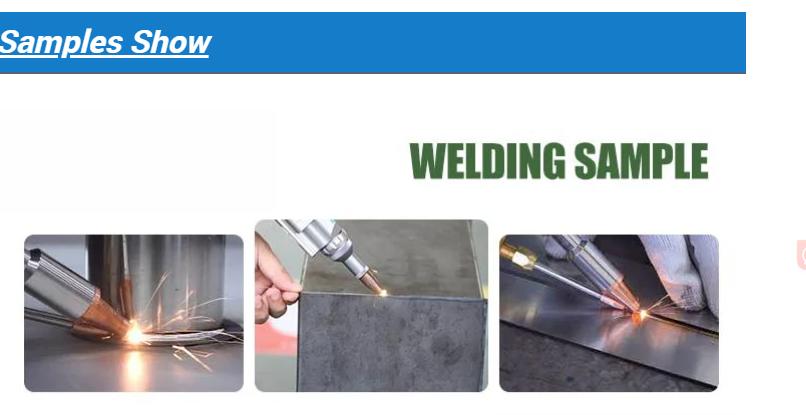

The product combines laser cutting, welding and cleaning functions in a single, compact device, marking a huge advance in efficiency, versatility and cost-effectiveness.

Advantages:

●Enhanced Productivity: By integrating three essential processes into one machine, manufacturers can streamline their operations, significantly reducing production time and increasing throughput.

●Cost Savings: The efficiency and versatility of the 3-in-1 machine translate into cost savings for businesses, eliminating the need for multiple specialized machines and reducing labor costs associated with manual processes.

●Quality Assurance: With precise cutting, welding, and cleaning capabilities, the machine ensures consistent quality across all stages of production, minimizing errors and rework.

●Accuracy and repeatability: This 3-in-1 laser uses advanced laser technology for excellent accuracy and repeatability, ensuring consistent results for every cut, weld and cleaning, eliminating errors and instability.

●Fast cutting and welding speed: The use of high energy laser beam greatly improves the cutting and welding speed, greatly shorting the production cycle and improving production efficiency.

●Efficient cleaning process: The laser cleaning function can quickly and thoroughly remove surface dirt, oxides and coatings without damaging the substrate surface, avoiding the damage and residue that may be caused by traditional cleaning methods.

●Multi-material adaptability: This 3-in-1 laser is suitable for a wide range of materials, including metals, plastics, ceramics, etc., providing users with a wider range of applications and greater flexibility.

●Environmental protection and energy saving: Compared with traditional methods, laser processing does not require additional consumption of large amounts of energy or chemical substances, reducing energy consumption and environmental pollution, in line with the requirements of sustainable development.

Applications:

●Automotive Manufacturing: In the automotive manufacturing process, this 3-in-1 laser can be used to cut body panels, weld body parts, and clean the coating to ensure the quality of the finish.

●Aerospace industry: Used in the cutting, welding and cleaning of aerospace components, such as the manufacture of aircraft structures and engine components.

●Electronics industry: Suitable for the manufacture of components for electronic products, such as the cutting, welding and cleaning of circuit boards, as well as processing processes in semiconductor production.

●Metalworking: Used for cutting and welding metallic materials, such as steel, aluminum alloys and stainless steel, as well as cleaning metal surfaces to remove oxides and contaminants.

●Medical device manufacturing: Components that can be used to make medical devices, such as cutting, welding and cleaning surgical instruments, medical devices and implants.

Jinan Gold Mark CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Email: cathy@goldmarklaser.com

WeChat/WhatsApp: 008615589979166

Post time: Mar-12-2024