-

How to deal with burrs on laser cutting corners? Tips to eliminate corner burrs!

Causes of corner burrs: When cutting stainless steel and iron plates, straight-line cutting usually does not cause problems, but burrs are easily generated at corners. This is because the cutting speed at the corners changes. When the laser of the fiber laser gas cutting...Read more -

The laser cutting machine needs to pay attention to the following principles and precautions when cutting high-reflective materials

When it comes to laser cutting machines cutting high-reflective materials, we need to pay special attention. The characteristics of high-reflective materials make the cutting process more challenging because most of the laser energy will be reflected rather than absorbed...Read more -

Knowledge sharing: Selection and difference of laser cutting machine nozzles

There are three common cutting processes for laser cutting machines when cutting carbon steel: Positive focus double-jet cutting Use a double-layer nozzle with an embedded inner core. The commonly used nozzle caliber is 1.0-1.8mm. Suitable for medium and thin plates, the...Read more -

You may not know the details about fiber laser cutting machines!

The fiber laser cutting machine outputs a high-energy density laser beam through a fiber laser and gathers it on the surface of the workpiece. The area illuminated by ultra-fine focal spot on the workpiece instantly melts and vaporizes. Automatic cutting is achieved by m...Read more -

Introduction to the Jewelry Laser Welding Machine?

The Jewelry Laser Welding Machine is specialized equipment designed for the jewelry manufacturing industry, utilizing laser technology for the welding process. This state-of-the-art technology is characterized by its precision, efficiency, and versatility, completely tra...Read more -

The difference between CW laser cleaning machine and Pulse laser cleaning machine

Continuous laser cleaning machines and pulsed laser cleaning machines are two common types of laser cleaning equipment, and they differ in cleaning principles, applicable scenarios, as well as advantages and disadvantages. Cleaning Principles: • Continuous Laser Cleaning...Read more -

What you must know about fiber laser cutting machines

The fiber laser machine is one of the latest developments in laser cutting technology, offering unprecedented speed and precision in the metalworking industry. But like most terms, fiber laser cutting sounds complicated. So what is it? ...Read more -

Russia METALLOOBRABOTKA 2024

Gold Mark Laser is excited to announce its participation in METALLOOBRABOTKA 2024, a prestigious industrial trade show in . The event will take place at the Expocentre Fairgrounds, Moscow, Russia Moscow, Krasnopresnenskaya nab. ,14,123100 from May 20th to 24th, 2024. METALLOOBRABOTKA 2024 is a pl...Read more -

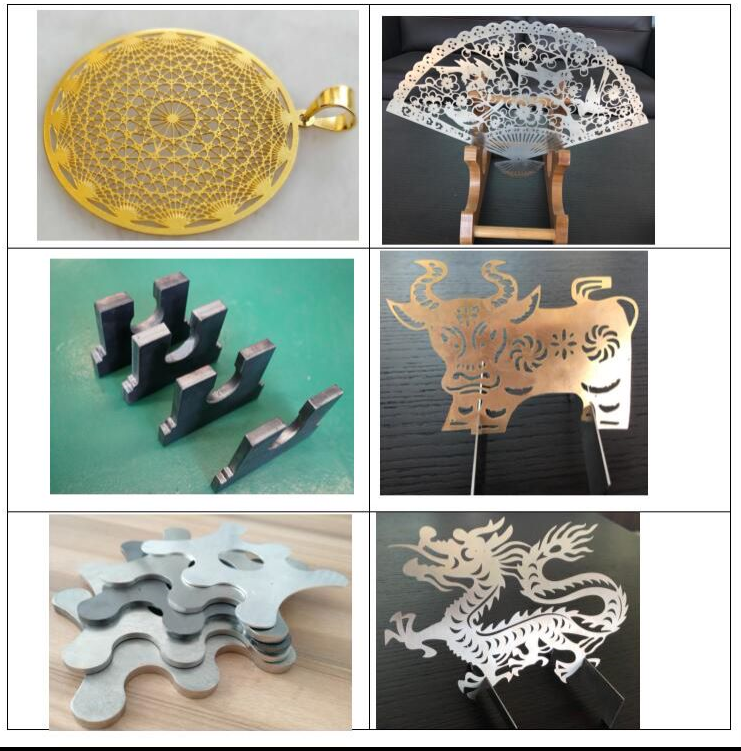

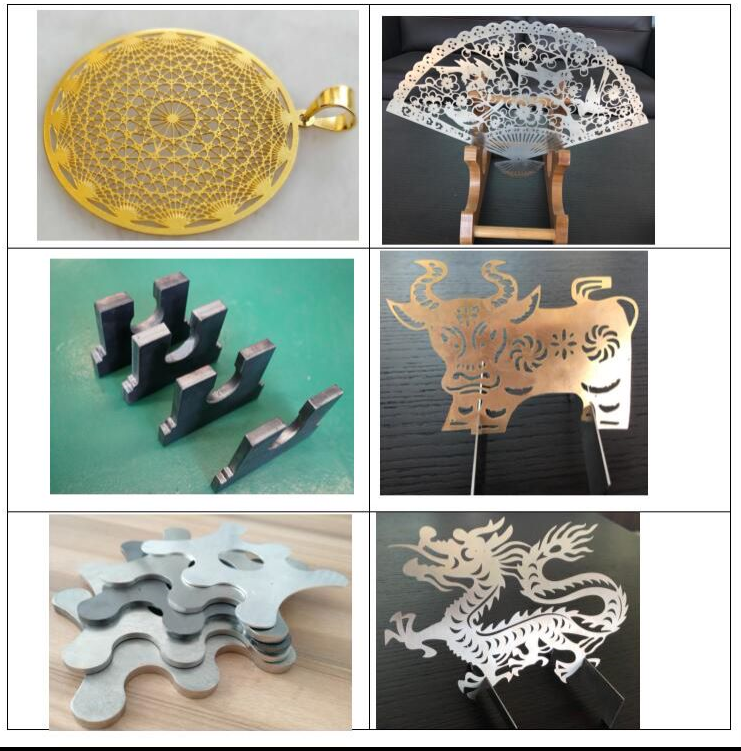

Fiber Laser Cutting Machine

Fiber Laser Cutting Machine – a cutting-edge solution for industries seeking unparalleled precision and efficiency in their cutting operations. This state-of-the-art equipment harnesses the power of fiber laser technology to provide unmatched performance across a spectrum of materials. Advantages...Read more -

Take You to Know Flying Fiber Laser Marking Machine

Fiber Laser Marking Machine utilizes a fiber laser to generate a laser beam. Through the optical system, the direction and focus of the laser beam are controlled, and marking is achieved by controlling the movement of the worktable. This enables fast, precise, and effici...Read more -

Do you know multi-functional laser equipment?

Definition: 4 in 1 laser machine has 4 functions: cutting; cleaning;welding; welding seam cleaning. It can realize the conversion between functions by replacing the focusing mirror and the nozzle.This machine has multiple functions, greatly improving work efficiency. It...Read more -

Fiber Laser Cutting Machine

The Fiber Laser Cutting Machine is an advanced tool designed for precise and efficient cutting tasks in various industries. It utilizes fiber laser technology to deliver superior performance and accuracy in cutting a wide range of materials. Advantages: High Precision: T...Read more -

What is metal laser cleaning?

Laser metal cleaning is a process that uses a laser beam to remove surface contaminants on metals, such as rust, paint, or oxides. The working principle of this process is to guide the laser beam to a clean surface, heat up pollutants, and cause them to evaporate or deco...Read more -

Gold Mark LASER Shines at SIMTOS 2024 with Record Success

Gold Mark Laser recently wrapped up a highly successful showcase at SIMTOS 2024, leaving a lasting impression on attendees and securing a multitude of on-site orders. Our presence at the event was marked by innovation, collaboration, and a commitment to delivering cutting-edge solutions to our ...Read more -

Do you really know about jewelry welding machines?

Laser Welding Machine for Jewelry Product Features 1. Laser spot welding uses imported ceramic concentrating cavity, high reflectivity, strong energy, high temperature resistance, corrosion resistance and long service life. 2. T...Read more -

Do you know pulse laser cleaning machine?

Definition: Pulse laser cleaning machine mainly uses pulse laser head. It irradiates the surface of the workpiece with a high-energy beam, so that the dirt and rust coating on the surface evaporates or peels off instantly. Finally achieve high speed and effective to get ...Read more