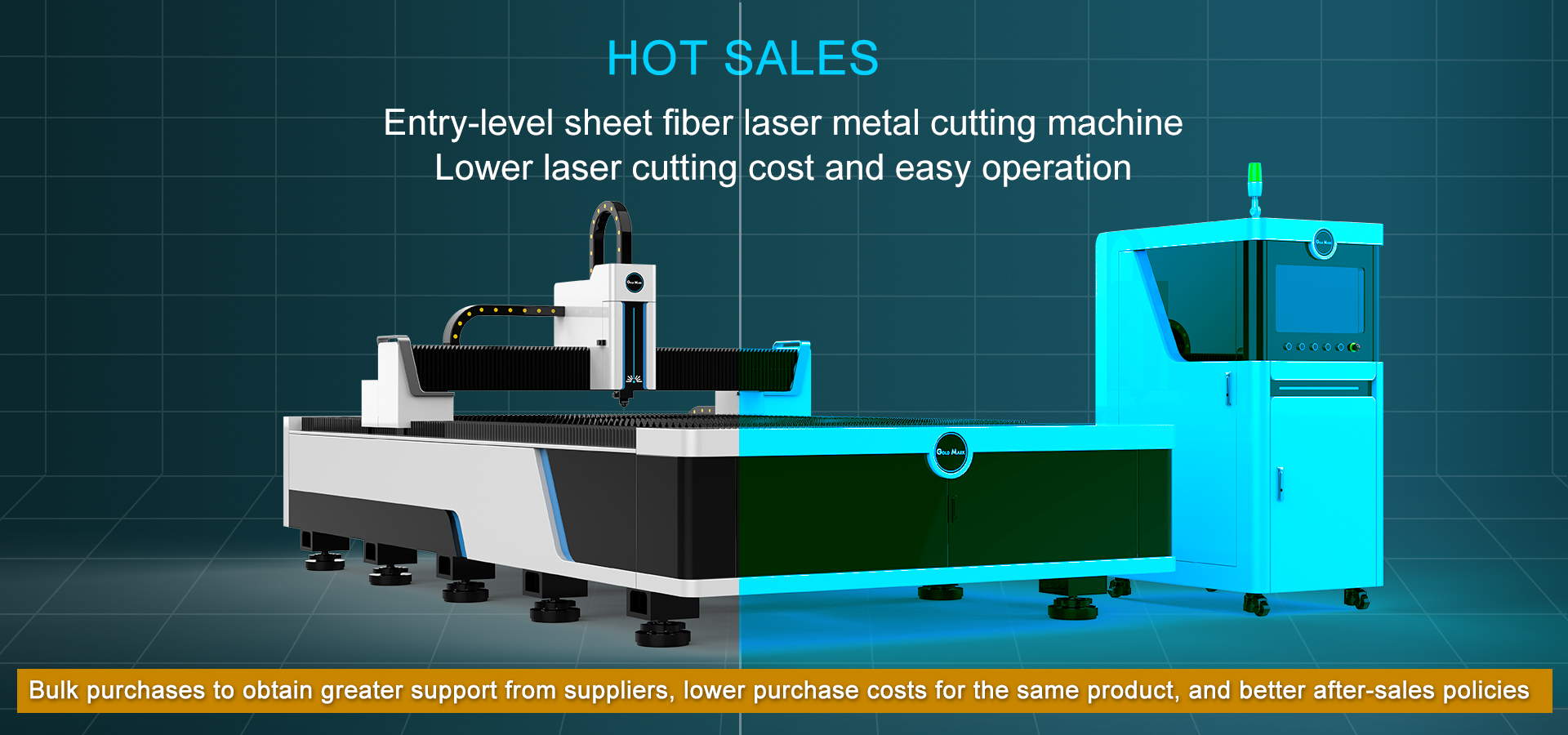

Factory Display

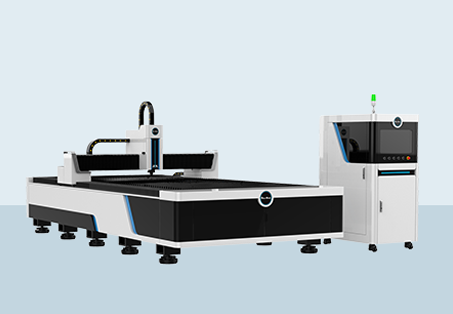

Intelligent partition of cutting machine

Without manual operation, it can focus automatically

-

Without Manual Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

-

Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

-

Long Service Life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

Autofocus Laser Cutting Head

The Segmented Rectangular Tube Welded Bed

The Segmented Rectangular Tube Welded Bed The internal structure of the bed adopts the aircraft metal honeycomb structure,which is welded by a number of rectangular tubes. Stiffeners are arranged insidethe tubes to increase the strength and tensile strength of the bed, it also increasesthe resistance and stability of the guide rail so as to effectively avoid thedeformation of the bed. High strength, stability, tensile strength, ensuring 20 years of use without distortion; Thickness of rectangular pipe wall is 10mm,and weights 4500 kg.

- 01Brand:MAX RAYCUS JPT IPG

- 02100000hours life time

- 03E stable,cost-efficient

- 04Free maintenance

Laser Source

SQUARE RAIL

Brand :Taiwan HIWIN

Advantage:Low noise,wear-resistant,smooth to keep fast Moving speed of laser head

Details:30mm width and 165 four pieces stock on every table to decrease the pressure of rail

- 01Brand:CYPCUT

- 02Details:edge seeking function and flying cutting function ,intelligent typesetting ect

- 03Supported Format:AI,BMP,DST,DWG,DXF,DXP,LAS,PLT,NC,GBX etc...

control system

Technical Parameters

- 01Machine ModelTSC-1313 / TSC-1530 / TSC-2040 / TSC-2065

- 02Machine1300 * 1300mm / 1500 * 3000mm / 2000 * 4000mm / 2000 * 6500mm

- 03Laser Power1kw / 2kw / 3kw / 4kw / 5kw / 6kw / 12kw / 20kw

- 04Laser GeneratorRaycus ( Optional : Max or IPG)

- 05Control SystemCypcut ( the other brand can be choose )

- 06Cutting HeadRaytool ( the other brand can be choose)

- 07Servo Motor and Driver SystemJapan Fuji ( Optional Yaskwa or Inovance)

- 08Water chillerS & A ( Hanli )

Product Specifications

Sample Display

Maintenance matters

| Laser cutting machine maintenance precautions | ||

| Maintenance period | Maintenance content | Maintenance target |

| Day | 1. Check whether the temperature setting of the chiller is normal (set temperature 20±1℃) | Ensure that the cooling water supplied to the laser is at normal temperature |

| 2. Check whether the water circuit seal, water temperature and water pressure of the chiller meet the requirements. | Ensure normal operation of equipment and prevent water leakage | |

| 3. Ensure that the working environment of the chiller is dry, clean and ventilated | Conducive to the good operation of the chiller | |

| Month | 1. Use Zhongbi detergent or high-quality soap to remove dirt on the surface of the chiller. Do not use benzene, acid, abrasive powder, steel brush, hot water, etc. for cleaning. | Ensure the surface of the chiller is clean |

| 2. Check whether the condenser is blocked by dirt. Please use compressed air or a brush to remove dust from the condenser to ensure that the surface of the chiller is clean. | Ensure the normal operation of the condenser | |

| 3. Clean the air filter: a. Open the panel where the air filter of the unit is assembled, pull up the air filter of the unit and pull it out; b. Use a vacuum cleaner, air spray gun and brush to remove the dust on the filter. After cleaning, if the filter is wet, shake it to dry before putting it back. c. Cleaning cycle: once every two weeks. If the dirt is serious, please clean it irregularly. | Prevent poor cooling resulting from poor cooling and burning out water pumps and compressors | |

| 4. Check the water quality of the water tank and follow up | Good water quality can ensure the normal operation of the laser | |

| 5. Check whether there is water leakage in the chiller pipeline | Ensure there is no water leakage in the chiller | |

| Each quarter | 1. Check the electrical components (such as switches, terminal blocks, etc.) and wipe them clean with a dry cloth | Ensure the surface of the electrical parts of the chiller is clean and extend its service life |

| 2. Replace the circulating water (distilled water), and clean the water tank and metal filter; | Make sure the laser is functioning properly | |

| If equipped with a ROFIN laser, the cooling water can be replaced once every six months after adding anti-corrosion inhibitors to the cooling water. If equipped with a PRC laser, the cooling water can be replaced once every six months after adding propylene glycol to the cooling water. | ||

| Notes: a. Place the chiller and water pipes away from dust. b. Pull out the power cord from the socket and wipe it clean; c. Clean the unit body: When cleaning the inside of the unit, do not let water splash on the electronic parts; d. Completely drain the laser, cutting head, and water cooler. exclude. | ||