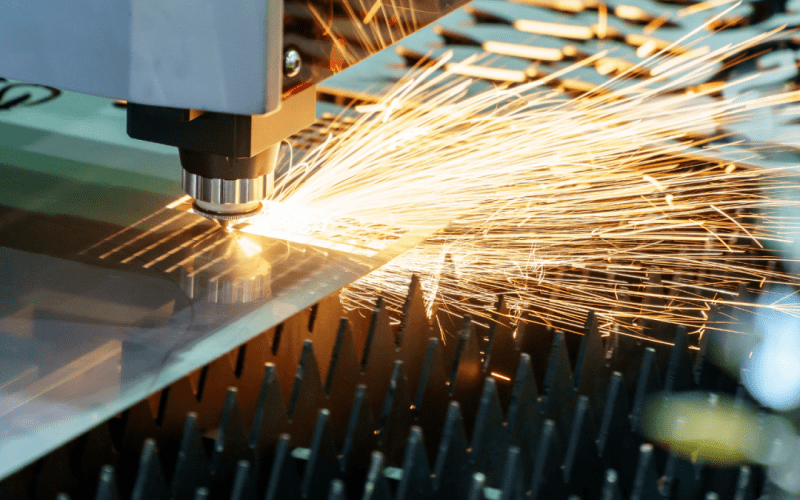

Fiber laser cutting machine in all walks of life is very widely used, it is mainly suitable for metal class material cutting processing, fiber laser cutting machine by the metal processing industry, the main reason is that the fiber laser cutting machine has a very high cutting accuracy. Many friends in the purchase of fiber laser cutting machine, after using a period of time, the cutting accuracy of the machine will appear a certain error, in order to maintain the normal operation of the process parameters, we need to master the accuracy of the debugging method, the following follow the Gold Mark laser to learn the accuracy of the fiber laser cutting machine debugging three considerations.

(1) the focus of the laser spot is adjusted to the smallest when the initial effect of point shooting to establish the size of the spot effect to determine the focal position, we just need to recognize the laser spot to the smallest, then this position is the best processing focal point, and then start processing work.

(2) In the former part of the laser cutting machine debugging, we can use some debugging paper, workpiece scrap to point to determine the accuracy of the focal position, moving up and down the height of the laser head position, the laser spot size when pointing will have a different size change. Multiple adjustments to different positions to find the smallest one spot position to determine the focal length and the best position of the laser head.

(3) laser cutting machine after installation, will be installed in the CNC cutting nozzle on a scribing device, through the scribing device to draw a simulated cutting graphics, simulated graphics for a 1m square. A circle with a diameter of 1m is built in and diagonal lines are scribed on each of the four corners. After scribing, a measuring tool is used to measure whether the scribed circle is tangent to the four sides of the square. The distance between the diagonal and the intersection of the two sides of the square should be 0.5 m. By testing the distance between the diagonal and the intersection, you can determine the cutting accuracy of the machine. This is real experience!

Jinan Gold Mark CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Post time: Apr-29-2021