We’ll make each individual effort to become exceptional and ideal, and speed up our steps for standing inside the rank of worldwide top-grade and high-tech enterprises for OEM Factory for China Gold Silver Metal Ring Necklace Bangle Chain Desktop Small Portable Jewelry Laser Welding Machine, We will wholeheartedly welcome all purchasers from the industry the two at home and abroad to cooperate hand in hand, and produce a bright foreseeable future jointly.

We’ll make each individual effort to become exceptional and ideal, and speed up our steps for standing inside the rank of worldwide top-grade and high-tech enterprises for China Laser Welding Machine, Fiber Welding Machine, In order to meet our market demands, we now have paied more attention to the quality of our solutions and services. Now we can meet customers’ special requirements for special designs. We persistently develop our enterprise spirit “quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

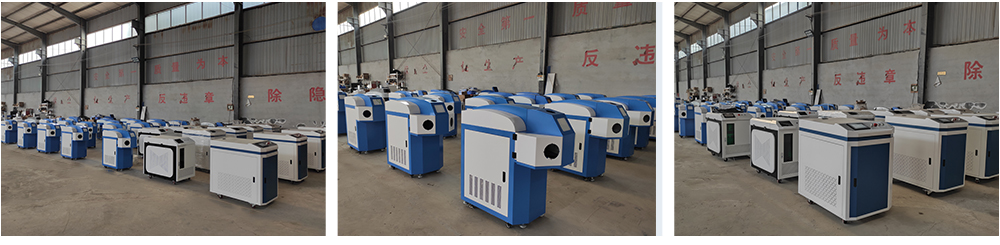

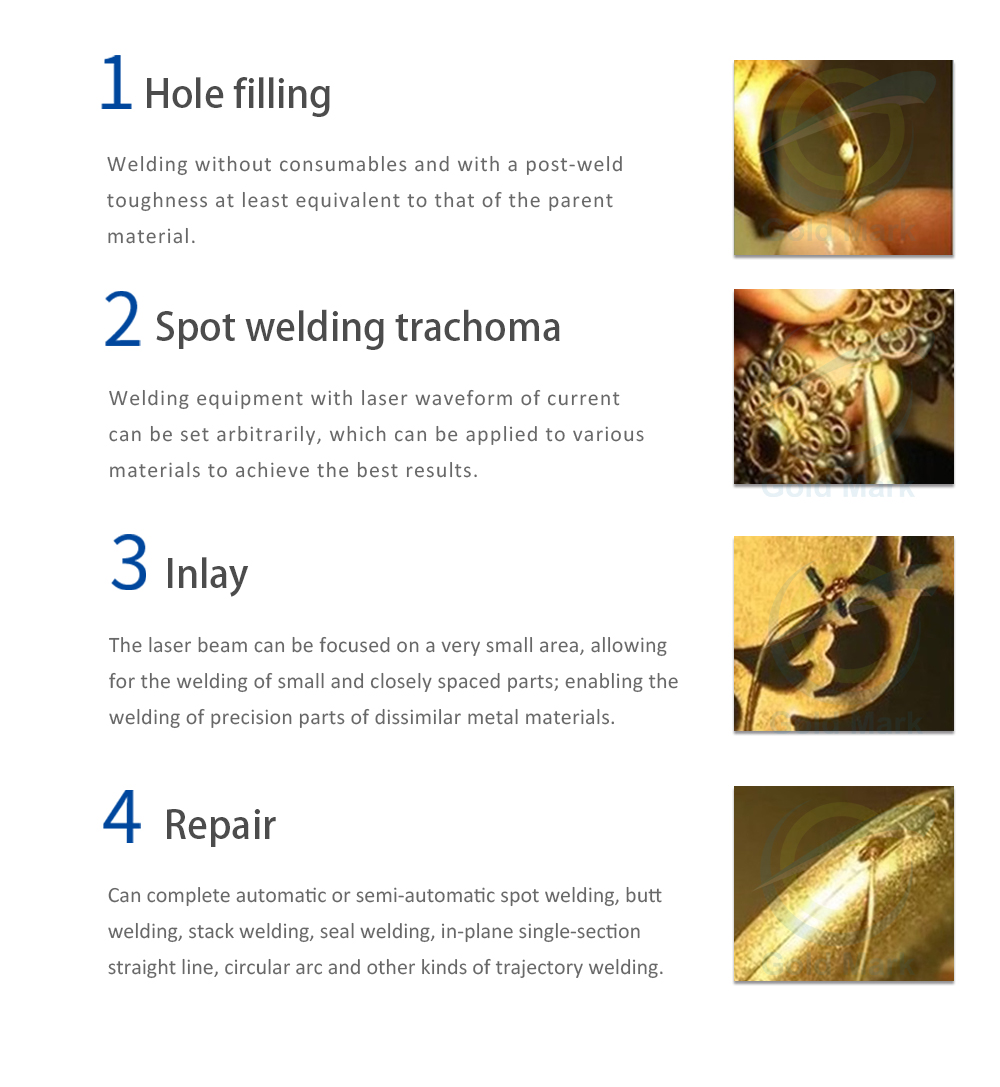

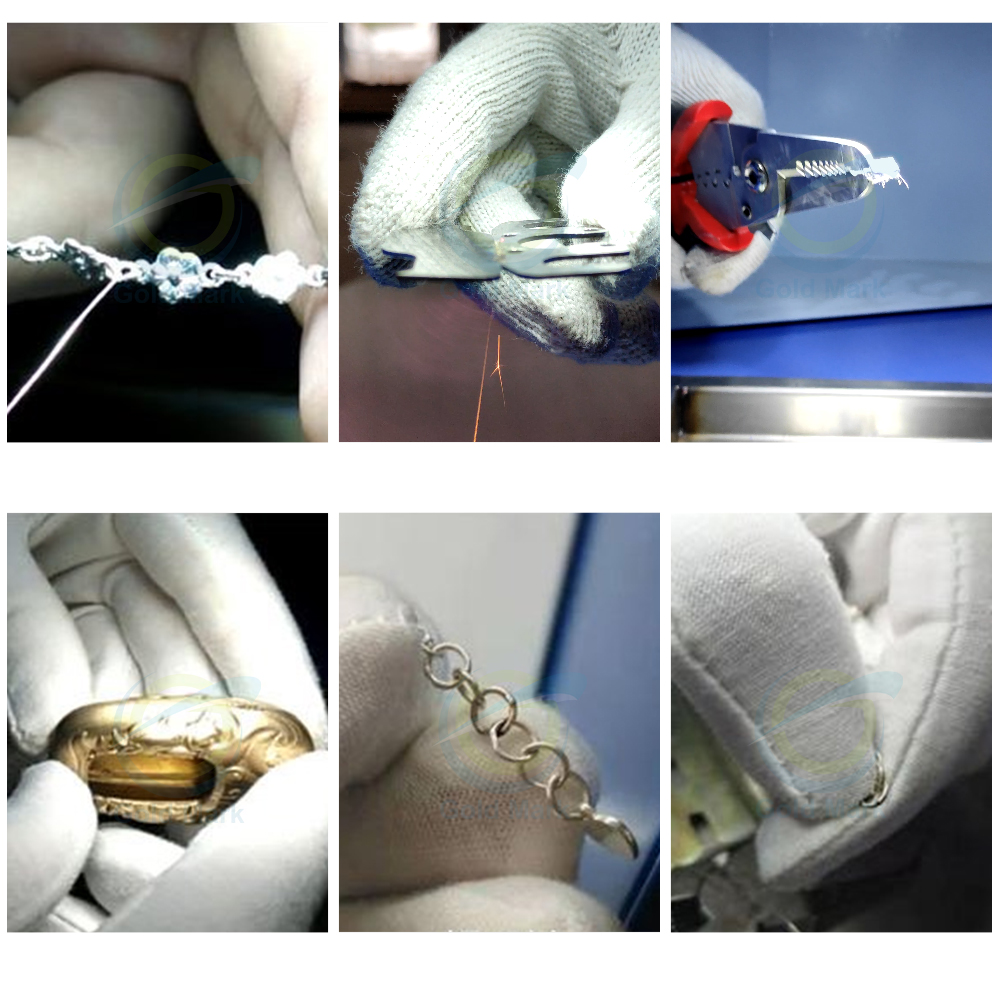

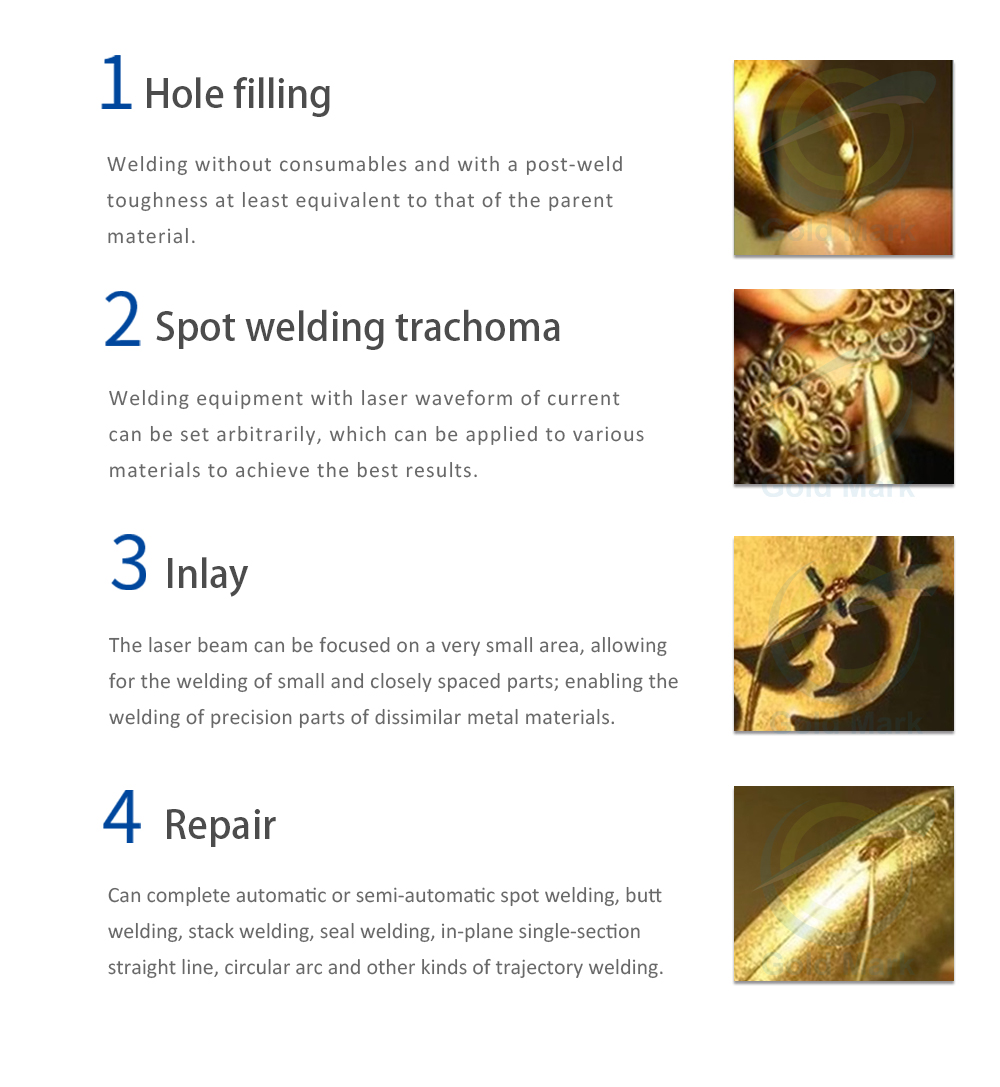

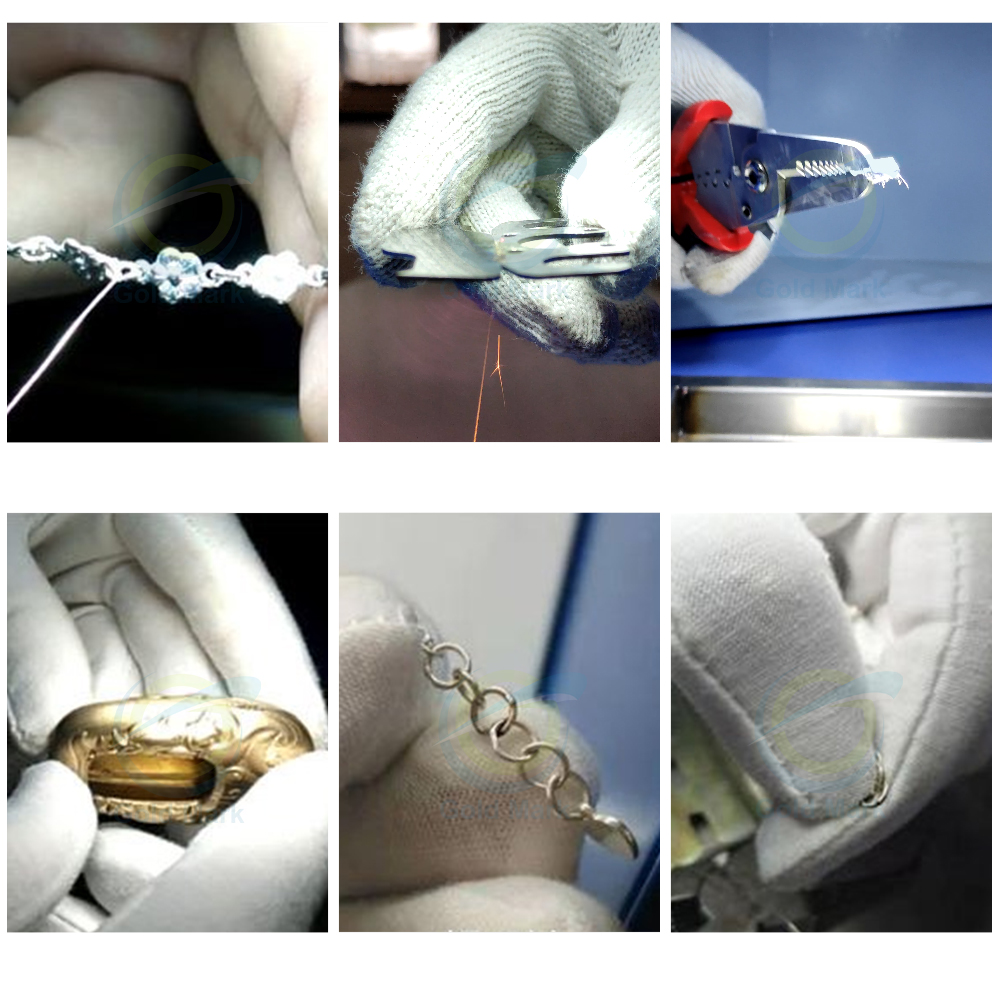

This laser spot welding machine is specially used for gold and silver jewelry, golf balls, electronic components to fill holes, spot welding trachoma, welding inlay, etc.. The welding is firm, beautiful, no deformation, simple operation, easy to learn and use, etc. It has the advantages of fast speed, high efficiency, large depth, small deformation, small heat-affected zone, etc. The welding quality is high, and the welded joint is pollution-free and environmentally friendly.

Widely used in cell phone communication, electronic components, new energy,jewelry and accessories, hardware products, precision instruments, auto parts, craft gifts and other industries.

Micro parts precision processing including: jewelry, jewelry, golf head and aluminum alloy denture, etc., especially suitable for gold and silver jewelry patching holes, spot welding trachoma, repairing seam lines and inlay parts claw foot parts, etc.

|

Model

|

LM-200 Laser Welding Machine

|

|

Output Power

|

100 W I 200 W I 300 W – based on requirement

|

|

Single-pulse energy

|

0-100 J

|

|

Machine Design Type

|

Desktop I Vertical

|

|

Laser Source

|

ND: YAG

|

|

Laser Wavelength

|

1064 nm

|

|

Pump lamp

|

Pulsed Xenon Lamp

|

|

Pulse Width

|

0.1.15 ms adjustable

|

|

Pulse Repeated Frequency

|

1 — 20 Hz adjustable

|

|

Welding spot diameter

|

0.2-1.5 mm adjustable

|

|

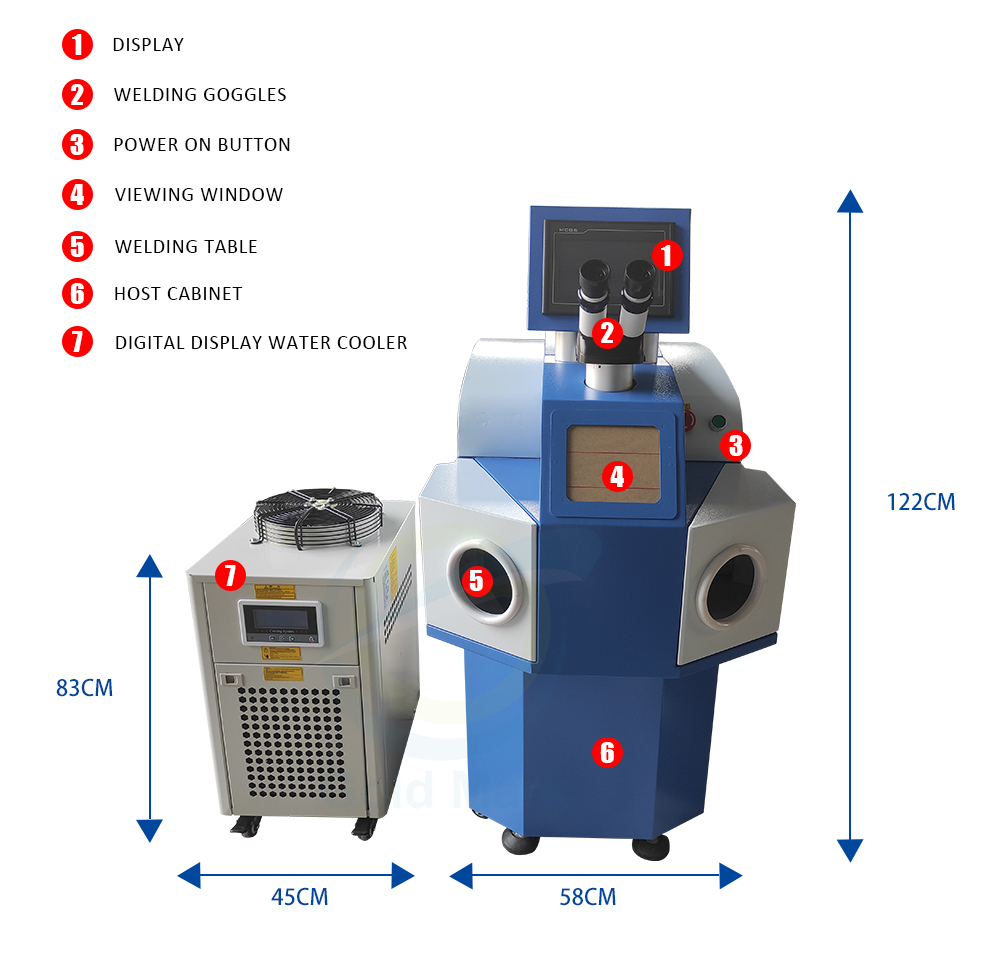

Observing System

|

Microscope I CCD – based on requirement

|

|

Cooling System

|

Water chiller

|

|

Power Supply

|

Single Phase AC 220V ± 10%, 50Hz I 60HZ, 4 KW

|

|

Running Environment

|

Temperature 5°C-28°C Humidity 5%-70%

|

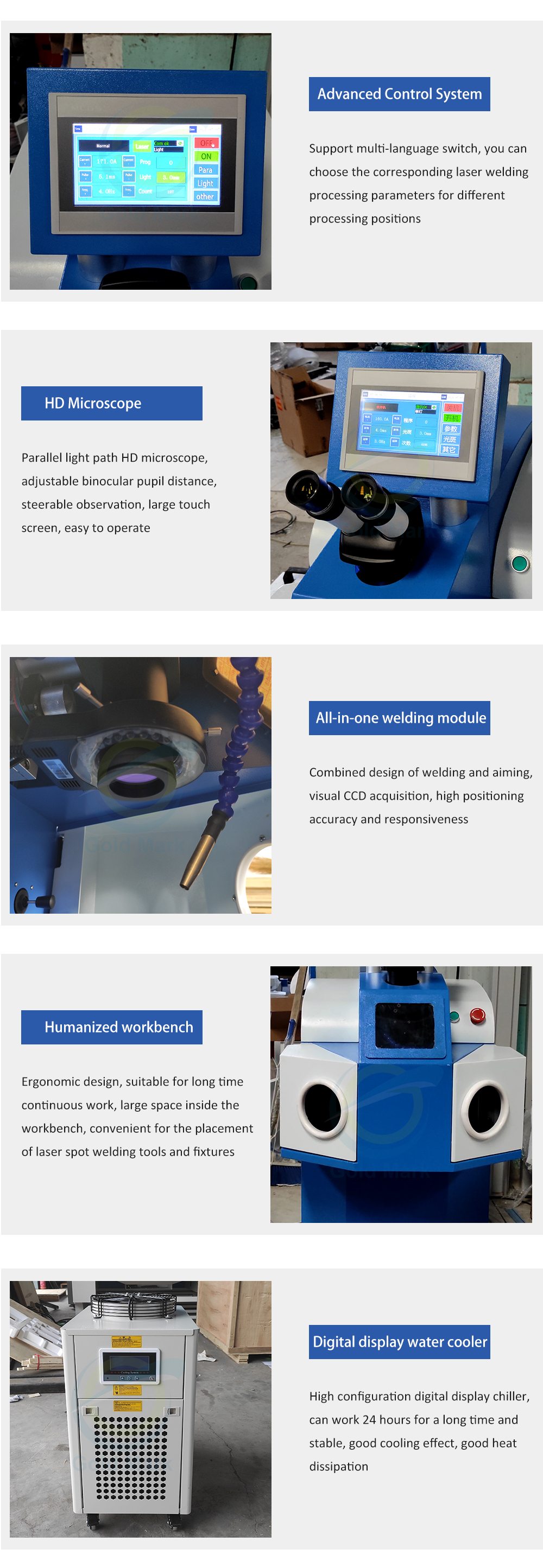

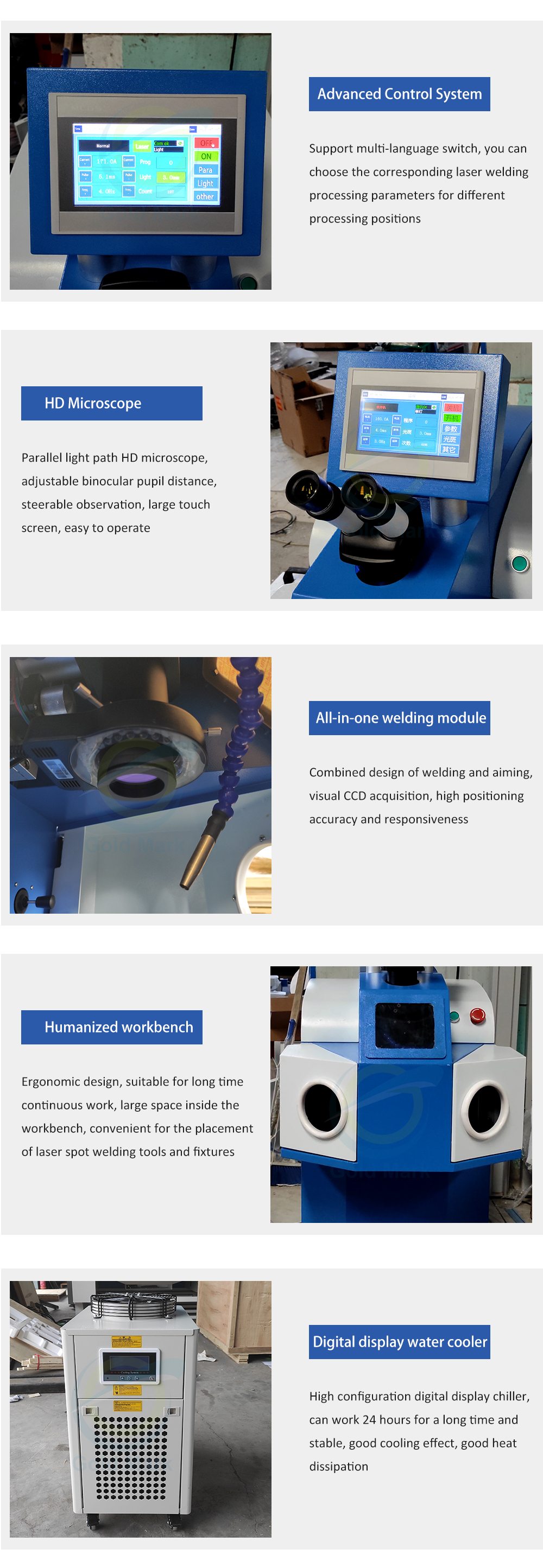

● Energy, pulse width, frequency, spot size, etc. can be adjusted in a wide range to achieve a variety of welding effects. Parameters are adjusted by the control lever inside the closed cavity, simple and easy to operate .

● Adopting British imported ceramic spotting cavity, corrosion resistant, high temperature resistant, high photoelectric conversion efficiency, spotting cavity life (8-10 years), xenon lamp life over 8 million times.

● Adopt the world’s advanced automatic shading system to avoid the stimulation of eyes during working hours.

● With 24-hour continuous working capability, the whole machine has stable working performance and is maintenance-free within 10000 hours.

● Humanized design, ergonomic, long working hours without fatigue.